In the meticulous world of paper engineering, the art of origami: precision folds and delicate cuts represents a fascinating intersection of mathematics, artistic expression, and engineering principles. This ancient Japanese practice has evolved from simple paper folding into a sophisticated craft with applications ranging from recreational art to industrial design. The principles that guide origami masters also inform modern manufacturing processes, including those used in creating precise gasket material for various industrial applications. What makes this connection particularly noteworthy is how the same attention to detail and understanding of material properties applies across these seemingly disparate fields.

The foundation of paper precision

The art of origami: precision folds and delicate cuts begins with an understanding of material properties. Just as traditional origami practitioners must comprehend how paper responds to folding and cutting, industrial fabricators must understand the behavior of gasket sheets under various conditions. This fundamental knowledge forms the basis for both artistic expression and functional engineering.

Traditional origami relies on precise creases and strategic folds to transform a flat sheet into a three-dimensional structure. Similarly, gasket fabrication requires exact measurements and cuts to ensure proper sealing and performance in mechanical systems. The precision in both disciplines isn’t merely aesthetic—it’s functional. A poorly executed fold in origami ruins the entire piece, just as an imprecise cut in gasket material can lead to mechanical failure.

Have you ever considered how the principles of material manipulation cross boundaries between art and industry? The connection becomes clearer when examining the tools and techniques used in both fields.

Modern techniques and traditional principles

Today’s origami artists often employ specialized tools for precision work—bone folders for creating sharp creases, precision knives for delicate cuts, and measurement tools for maintaining proportions. These tools help maintain the integrity of the paper while achieving increasingly complex designs. The art of origami: precision folds and delicate cuts has advanced dramatically with these tools, allowing for creations that would have been impossible for earlier practitioners.

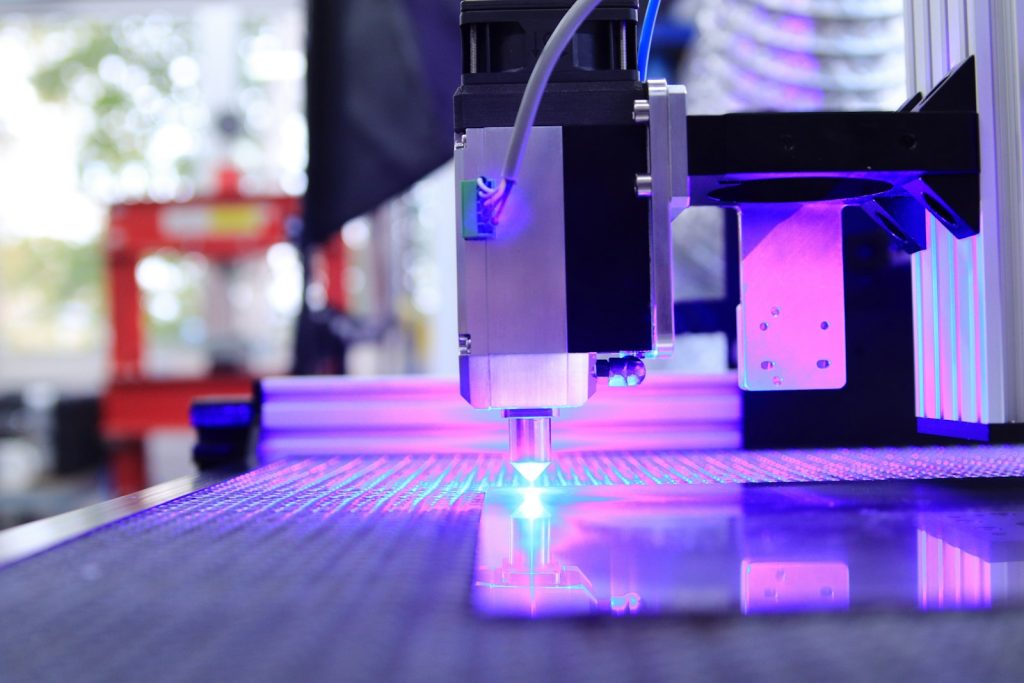

In parallel, the gasket industry has embraced technological advancements while maintaining fundamental principles of material manipulation. Laser cutting gaskets represents perhaps the most significant advancement in precision fabrication. This technology allows for intricate patterns and precise dimensions that would be difficult or impossible to achieve with traditional die-cutting methods. The computer-controlled laser beam creates clean edges and can handle complex geometries with remarkable accuracy.

When fabricating gasket sheets, the same principles of material understanding, precise measurement, and careful cutting apply as in artistic origami. The difference lies primarily in scale, materials, and application rather than in fundamental approach. Both require a deep understanding of how materials respond to manipulation and how precise cuts and folds create the desired outcome.

Material considerations in precision work

Just as origami masters carefully select paper for specific properties—thickness, flexibility, texture, and strength—gasket manufacturers must choose appropriate gasket material for each application. The selection process considers operating temperature, chemical exposure, pressure requirements, and longevity.

High-temperature applications might require ceramic or metal gasket material, while chemical processing often demands fluoropolymer gaskets resistant to corrosive substances. The art of origami: precision folds and delicate cuts teaches us that material selection is not merely a technical decision but a foundational choice that determines what’s possible in the finished product.

The relationship between material and technique becomes particularly important when working with specialty gasket sheets. These engineered materials often combine multiple properties—such as chemical resistance, temperature tolerance, and compressibility—in a single sheet. Working with such materials requires specialized knowledge and equipment, much like creating complex origami with specialty papers demands expertise beyond basic folding techniques.

Precision cutting technologies

The evolution of cutting technology has revolutionized both artistic paper crafting and industrial gasket fabrication. While traditional origami relies primarily on folding rather than cutting, modern interpretations often incorporate strategic cuts to achieve complex forms. This adaptation, sometimes called kirigami, expands the possibilities of paper art through controlled cutting patterns.

In gasket manufacturing, laser cutting gaskets has become the gold standard for precision work. The advantages are numerous:

1. Exceptional accuracy with tolerances as tight as ±0.05mm, ensuring perfect fits in critical applications

The laser cutting process eliminates the tooling costs associated with die cutting and allows for rapid prototyping and design iterations. This technology can handle materials ranging from thin PTFE sheets to thick compressed fiber compositions, adapting power and speed settings to achieve clean cuts without material damage.

For you as an engineer or procurement specialist, understanding these cutting capabilities means recognizing how precision manufacturing can solve sealing challenges in your specific applications. The same attention to detail that makes origami beautiful also makes industrial gaskets functional and reliable.

The mathematics behind the art

Perhaps the most surprising connection between the art of origami: precision folds and delicate cuts and industrial gasket design is the shared mathematical foundation. Origami has long been studied by mathematicians for its geometric principles and transformative properties. The discipline even has its own set of axioms and theorems governing what is possible with a single sheet of paper.

These mathematical principles—dealing with angles, planes, and transformations—find parallel applications in gasket design. Engineers must account for material deformation under compression, fluid dynamics at sealing interfaces, and thermal expansion characteristics. The precision in gasket sheets fabrication isn’t arbitrary but based on calculated requirements for specific operating conditions.

When laser cutting gaskets, these mathematical principles guide the programming of cut patterns. The precision afforded by computer-controlled cutting allows for implementation of complex geometries that optimize sealing performance while minimizing material waste. This represents a perfect marriage of artistic precision and engineering pragmatism.

Applying precision principles in practice

The practical application of these precision principles extends beyond aesthetic appeal or basic functionality. In critical industries such as aerospace, pharmaceutical manufacturing, or chemical processing, the integrity of gasket seals can have safety implications. The lessons of meticulous attention to detail from the art of origami: precision folds and delicate cuts translate directly to quality control procedures in gasket manufacturing.

For facilities managers and maintenance engineers, understanding these principles helps in selecting appropriate gasket solutions for specific applications. The wrong material or imprecise dimensions can lead to leaks, contamination, or equipment damage—consequences far more serious than a misfolded origami crane.

As technology advances, both origami artists and gasket manufacturers continue to push boundaries of what’s possible through precision. New materials, cutting technologies, and design approaches expand possibilities while maintaining the fundamental principles that have guided these disciplines for generations. The shared emphasis on exactness, material understanding, and thoughtful execution continues to unite these seemingly different fields in surprising ways.