Heat exchanger gaskets play a vital role in maintaining the efficiency and safety of thermal transfer systems across numerous industries. These specialized sealing components prevent fluid leakage between the plates or elements of heat exchangers, ensuring optimal performance and preventing cross-contamination. The integrity of these sealing solutions directly impacts operational efficiency, maintenance costs, and system longevity.

Material Considerations for Optimal Performance

The selection of appropriate gasket materials represents one of the most crucial decisions in heat exchanger design. Engineers must consider multiple factors including operating temperature ranges, chemical compatibility, compression set resistance, and expected service life. Common materials include:

- EPDM (Ethylene Propylene Diene Monomer) for water and steam applications

- NBR (Nitrile Butadiene Rubber) for oil and fuel resistance

- FKM/Viton for high-temperature and aggressive chemical environments

- PTFE (Polytetrafluoroethylene) for nearly universal chemical resistance

- Graphite composites for extreme temperature applications

Each material offers distinct advantages depending on the specific operating conditions and fluid media. The wrong material selection can lead to premature failure, contamination issues, and unplanned downtime.

The Evolution of Precision: Laser Cut Gasket Technology

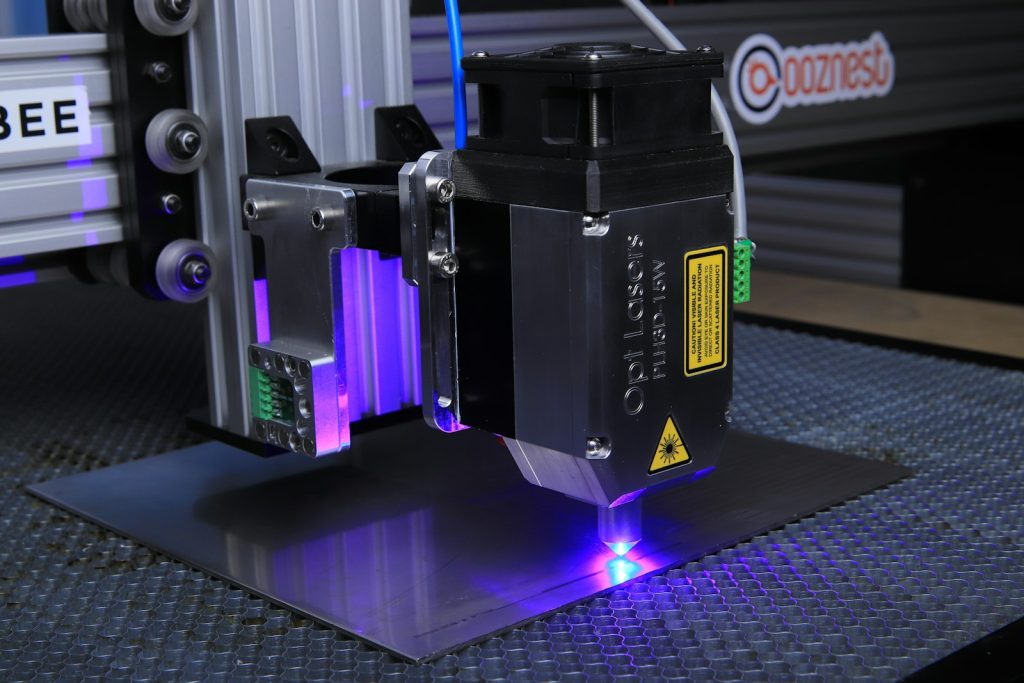

Traditional die-cutting methods have increasingly given way to advanced laser cut gasket manufacturing. This technological advancement has revolutionized the precision and capabilities of gasket production. Laser cutting technology utilizes computer-controlled systems to create intricate patterns and precise dimensions with tolerances often measured in thousandths of an inch.

The laser cut gasket approach offers several significant advantages:

- Near-perfect dimensional accuracy

- Elimination of tooling costs for custom designs

- Ability to produce complex geometries not possible with traditional methods

- Reduction in material waste

- Rapid prototyping capabilities

- Clean, burr-free edges that enhance sealing performance

Addressing Common Sealing Challenges

Heat exchanger systems present unique sealing challenges that require specialized solutions. Thermal cycling, which causes repeated expansion and contraction, can lead to gasket compression set and subsequent leakage. Pressure fluctuations similarly stress sealing components, while chemical compatibility issues may cause premature deterioration.

Modern heat exchanger gaskets incorporate design features specifically engineered to address these challenges. Variable thickness profiles accommodate surface irregularities, while controlled compression stops prevent over-compression that might damage the gasket material. Advanced laser cut gasket designs can incorporate multiple sealing elements and pressure-relief features within a single component.

Customization and Application-Specific Solutions

Every heat exchange system presents unique requirements based on industry, application, and operating parameters. The precision of laser cutting technology enables manufacturers to create application-specific solutions without the traditional constraints of die-cutting tools.

For pharmaceutical and food processing applications, laser cut gaskets can be produced from FDA-compliant materials with extremely smooth surface finishes to prevent bacterial growth. In contrast, chemical processing might require multilayer gaskets with PTFE faces and more resilient cores. Power generation applications often demand high-temperature solutions with enhanced compression recovery.

Installation and Maintenance Best Practices

Even the highest quality heat exchanger gaskets will fail prematurely if improperly installed or maintained. Proper installation requires clean, undamaged sealing surfaces, appropriate compression, and correct torque sequences for fasteners. Technicians should follow manufacturer recommendations for lubricants and anti-seize compounds.

Maintenance programs should include regular inspection of gasket condition, checking for signs of compression set, chemical attack, or physical damage. Preventative replacement schedules based on operating conditions rather than waiting for failure can significantly reduce costly emergency shutdowns.

Industry Standards and Compliance

Heat exchanger gaskets must often comply with various industry standards and regulations. These may include pressure equipment directives, food contact approvals, emissions standards, and material certification requirements. Manufacturers of precision laser cut gasket products typically provide comprehensive documentation verifying compliance with relevant standards.

Emerging Innovations in Gasket Technology

The quest for perfect sealing continues to drive innovation in the field. Recent developments include nano-composite materials with enhanced temperature and chemical resistance, intelligent gaskets with embedded sensors for condition monitoring, and hybrid designs combining multiple materials for optimized performance.

Advanced laser cutting systems now offer multi-axis capabilities, allowing for specialized edge treatments and variable-depth cutting within a single gasket. These technological advancements continue to expand the possibilities for creating increasingly effective sealing solutions for the most demanding heat exchanger applications.

The Economic Impact of Superior Sealing

The true value of high-quality heat exchanger gaskets extends far beyond their purchase price. Premium sealing solutions, particularly precision laser cut gasket designs, deliver significant return on investment through extended service life, reduced maintenance requirements, improved thermal efficiency, and prevention of cross-contamination incidents.

In high-value processing applications, the cost of unplanned downtime due to gasket failure can easily exceed thousands of dollars per hour. This economic reality makes the investment in superior gasket technology a sound business decision for operations where reliability and efficiency are paramount concerns.